Abiding by the CWA and Managing Boat Wash Wastewater

Published on August 14, 2025The history of U.S. water quality regulation has many roots, tracing back to the heart of the nation. Ohio’s Cuyahoga River fire of 1969 alarmed the country and brought about the creation of the Environmental Protection Agency (EPA) the following year. Three years later, the Clean Water Act (CWA) was signed.

More recently, the CWA has undergone revisions, politics notwithstanding, largely on a path seeking clarity of definition. Administrations and agencies asked, “Which waterways are regulated?” Now in 2025, the CWA endures, and those wet spots on the map that fall under the stately designation of Waters of the United States (WOTUS) appear to have come slowly into focus. The list of regulated waterways includes the Great Lakes.

Common Challenges

Today, one of the common challenges for marinas to achieve compliance with the CWA is the management of boat wash wastewater. An integral part of boat maintenance, seasonal boat washing streamlines the hull by removing built-up aquatic life and consequently some bottom paint, too, therefore triggering a violation of the CWA.

In the 1980s, copper began replacing Tributyltin (TBT) as the primary biocide in anti-fouling paint after the latter proved extremely hazardous to marine life. Still less dangerous than TBT, elevated copper levels are seen as problematic to aquatic life.

In 2012-2013, the Ohio Sea Grant and Bowling Green State University performed a study at eight of Ohio’s Lake Erie marinas to evaluate copper levels in the nearshore sediment. “We discovered 20 times the amount of copper in the sediment where there are dedicated wash wells,” said Sarah Orlando, Ohio Clean Marinas program manager with Ohio Sea Grant.

A second study, in 2018, assessed the effectiveness of on-site capture and treatment to minimize hazardous disposal costs. “We found that while the wastewater can generate elevated levels of toxins in the water and sediment near a boat wash station, the fact that much of the bottom paint is composed of heavy metals works in our favor,” Orlando said. “By intercepting the water and allowing it to settle in holding tanks for a few days, an effective on-site pretreatment process is possible.” The research was leveraged for guidance in developing the boat wash capture and treatment systems in 2020 and beyond.

Educating Marinas

It’s been a key mission of the Ohio Clean Marinas Program to educate marina owners on safe management and disposal of boat wash wastewater and reaching compliance with the CWA. In 2018, following a new wave of CWA implementation in Ohio, the Ohio Clean Marinas held a stormwater and wastewater workshop. Attending marina owners learned of the changing regulation, but many walked away scratching their heads on how to reach compliance. “What we learned from that workshop is that a lot of marinas said, ‘You’re telling us this regulation changed. OK, now what?’ “ Orlando said.

The collective need for guidance prompted Ohio Clean Marinas to partner with the Ohio Department of Natural Resources to implement a boat wash station at Ohio’s Geneva State Park on Lake Erie as a model for Ohio’s marina industry. The Geneva facility is a state-of-the-art closed-loop system that treats the spent wash water with bromide and UV light, then reuses the water again and again, until ultimately a small quantity is hauled off site to a publicly owned treatment works (POTW).

A complete design-build from scratch with an engineer design process running several years long, Orlando recognizes that Geneva is not a one-size-fits-all system for marinas. What began as a one- to two-year project eventually doubled in schedule, and the now-all-too-familiar pandemic complications sent the price tag north of $200,000. Orlando said that the project included design criteria above and beyond an interest in simply complying with the CWA. The facility required extensive grading and new infrastructure for the boat wash system that, beyond contaminant capture, has the ability to adapt as an aquatic invasive species removal unit for zebra mussels and hydrilla.

While exemplary in function and stewardship, the Geneva model is not the only way. Putting these marinas in compliance and not putting them out of business is Orlando’s goal. Those marinas without deep pockets may pursue designs that leverage in-house labor, equipment or materials on site. Where money is short, other resources may allow for alternative design solutions. “At the end of the day, our goal is to help marinas understand best practices in protecting water quality, but also to help them thrive as a business in the same way,” Orlando said.

This project was one example of that balance of trying to walk that line. If a marina already has a wash pad and catch basin in place, a more basic boat wash system might be along the lines of $40,000 to $100,000 to develop, which Orlando said is still no small sum. Growing their knowledge base and curating resources for marinas to leverage is a long-term goal for Ohio Clean Marinas. The program continues to seek creative solutions focused on leveraging the existing infrastructure that some marinas do have.

Evaluate Options

Today, there are several anti-fouling paints advertised as eco-friendly. It’s a distinction that Orlando cautions to take with a grain of salt. “By and large, what guidance I’ve gotten is that we don’t have the time or capacity to go through every single bottom paint,” she said. “Let’s focus on not releasing any paint into the water.”

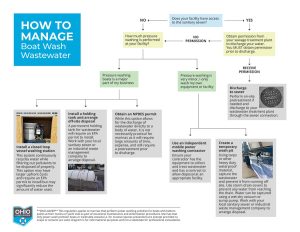

When evaluating boat wash practices, the first question for an owner to answer is whether or not their marina washes boats using anti-fouling paint. Following the affirmative, the second concern is finding a destination for spent boat wash water.

Where is the closest wastewater treatment plant to your marina? “With Geneva, the local sewer district does not have the capacity to process that wastewater,” Orlando said. “So, we set up a hauler to take that water to a sewer treatment plant.”

As with any improvement project, there are permits to consider before shovels touch the ground. However, understanding local wastewater plant capabilities might be a good place to start. The Ohio Clean Marinas Program is also available to help local marinas navigate this regulation and take part in protecting the one thing our industry can’t replace or live without: the water.

| Categories | |

| Tags |