Amped: The Power of Safe, Compliant Marina Electrical Systems

Published on April 7, 2024Electrical systems are both the pulse and the nervous system of marina life. Complex and code-driven, they work behind the scenes to assure that boaters, visitors and owners have a safe, functional and convenient experience. Yet, the design of these systems can be complicated. It requires meticulous and conservative adherence to regulations and an acute assessment of client needs, future-state demands and environmental inputs. Only then can the system succeed in the goal of keeping boats running and hearts beating.

Code Compliance

While requirements may vary slightly between states or local agencies, the prevailing standard to follow is the National Electrical Code (NEC) / NFPA 70. Updated and re-published by the National Fire Protection Association (NFPA) every three years, the NEC is considered the go-to electrical guide — and while not federal law — is mandated by most states and municipalities to regulate and enforce safe electrical installations.

Article 555 of the NEC is dedicated to marinas and boatyards and first appeared in the NEC in 1968, titled as “Boat Harbor Wiring.” In 1971, the title was updated to its existing name, and the content has evolved ever since. The most notable change took place in 2017 when it underwent a massive re-write to address a distressing and increasingly concerning issue: ground-fault protection. Ground-fault protection was added to the code to address the cause of multiple electric shock drowning accidents at marinas and waterfront facilities across the country. Article 555 was updated again in 2020 and 2023, which is today’s most current, designated guidance for marina electrical systems.

But what if a marina was built before any of these codes was written? Is it best to retrofit its existing infrastructure or start fresh altogether?

There isn’t a simple answer but instead a handful of questions that might guide marina owners in the right direction. One, is the existing system safe? A thorough inspection by a licensed electrical engineer or professional can help make the determination. Two, what boat vintages do most marina clients own and operate? Older boats are often the source of ground-fault issues, and newer boats have electrical systems vastly different than those of 50 or 60 years ago — not to mention, an overall greater electrical load due to the need

For marinas built before any electrical codes were written it is best to have a licensed electrical engineer conduct a thorough inspection.

to power all of today’s modern boating conveniences. Items such as coffee machines, computerized devices, televisions, hair dryers and more require “juice,” and the compound effect of that load on any given marina electrical infrastructure is only increasing. It is possible to retrofit things like power panels and breakers, but these retrofits may result in boaters tripping the entire feeder circuit and causing all their neighbors to lose power. That leads us to our third question: How close is the marina to needing a re-design or upgrade of other infrastructure? It is advisable to take an honest assessment of the condition of the property and weigh present-day functionality against the optimal future state. Sometimes a more comprehensive up-front investment in upgrades is the best long-term solution.

Systems for a Diverse Classification

When looking at an electrical upgrade for a marina, it is imperative to know the existing clientele and understand the needs of future clients. There are significant differences when considering who is going to occupy the slip. Most marinas can expect an eclectic mix of old boats and new, sailboats, houseboats, yachts, mega-yachts, electric boats and the occasional “DIY” experimental vessels, each with different needs and expectations for a safe, convenient user experience.

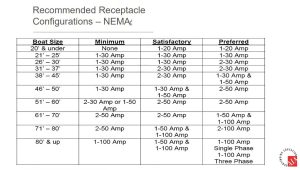

Can one electrical system accommodate them all? The short answer is yes, but it’s not always easy. The National Electrical Manufacturers Association (NEMA) has established recommendations for amperage per boat length and organized them into “Minimum,” “Satisfactory” and “Preferred” categories. This is an excellent starting point. That said, a licensed electrical engineer — along with input from marina management — is best suited to assess each individual marina’s situation and design the right system to match current and future needs. This professional will typically follow the NEMA recommendations for required power but will also review the “levels of diversification” within marina code that balance the number of outlets and power loads on a circuit with the size and length of wire needed to support the circuit. The longer the wire, the lower the voltage at the far end if the wire size is not selected correctly. If the voltage is permitted to drop too far, it will be problematic for the boat and its electronics, or it will require additional equipment on board to rectify the voltage. Knowing how many boats of what size and age each power pedestal will support can help determine how much amperage is needed and how a marina might be laid out. For instance, if a marina is considering expansion to accommodate mega yachts, the slips for those large vessels ideally would not be located at the far end of the dock because of their high-power demand. Placing them at the end would increase the size of the wire needed and the cost of the circuit.

Another design consideration should be voltage requirements of the boats and the available voltages from the utility. Utility services have changed over the years. At one time the most common service was a 240-volt, high-leg, 3-phase. This drove the boating industry to design boats with 240-volt, 1 phase systems on board. However, 240-volt, high-leg services have inherent risks associated with them, are now considered unsafe and are being phased out by many electrical utility companies — or offered only as single-phase. Instead, 208VAC or 480VAC services have become more common. Today, 480VAC power can be distributed throughout a marina to minimize voltage drop and the cost of long circuits. This helps to lower the installation costs, but any maintenance or modification of these systems can only be done by authorized personnel along with a licensed electrical engineer. While running higher voltages on shore affords the opportunity to keep installation costs lower, once a circuit is extended out over the water, the voltage of the circuit is restricted to under 600 volts.

Systems for Diverse Environments

Marinas also need to ensure that their electrical utilities are properly designed for the environment. Code and best practices change between saltwater and freshwater scenarios; in marinas within floodplains vs areas of highly fluctuating water levels; and in locations with winter ice shelf conditions, hurricane and high wind zones, and more.

A new transient marina on the Ohio River in Owensboro, Kentucky, will have electric conduit run from a utility vault on shore down through a braided, flexible steel cable, which is affixed between one of the fixed platforms

Electrical design for marinas located in saltwater environments, for example, means need different materials and methods of installation to assure that the salt doesn’t corrode the connection points. This may mean utilizing corrosion-resistant materials more frequently or utilizing more expensive materials than would typically be necessary.

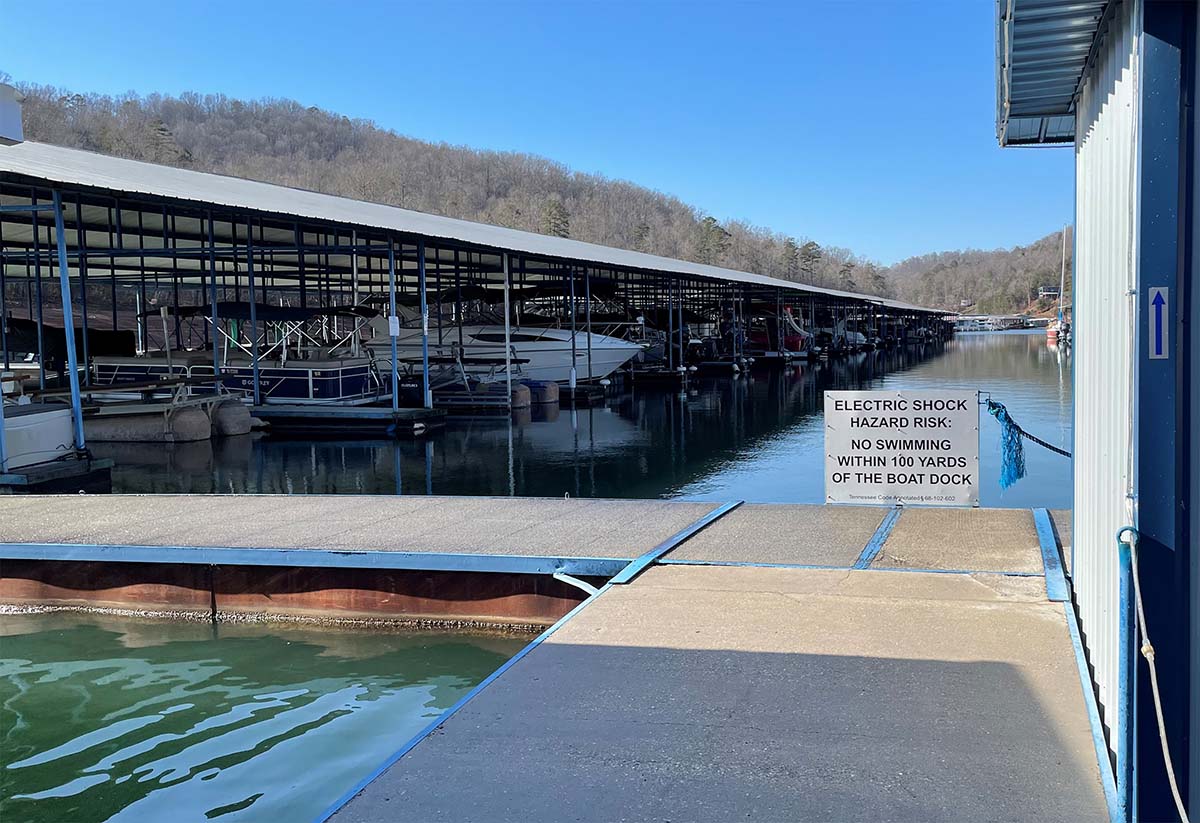

A challenge with freshwater environments is they pose a greater risk of electrical shock to humans. This is due to differences in conductivity between salt and fresh bodies of water such as lakes and rivers. Saltwater has a naturally high conductivity rate and low resistance, meaning that any leaking current in the water tends to be transported around a human body rather than through it. Conversely, electrical currents in freshwater will go through a human body as the path of lowest resistance, because the water has low conductivity and high resistance (abut 70 times more resistance than saltwater). Design for electrical systems at freshwater marinas requires extra diligence and education on the behalf of boaters to assure operations are as safe as possible. Some states are going above and beyond to enforce safe use. State of Tennessee Code Title 68, for instance, requires that all Tennessee public marinas and docks be inspected by the State Fire Marshal’s Office (SFMO) every five years. Marinas must also install permanent safety signs with print legible at 80 feet, indicating the area has an electric shock hazard risk and no swimming is allowed within 100 yards of a boat dock.

Marinas dealing with brackish waters should take the same precautions as those in freshwater locations. Bodies of water can be various degrees of brackish or fresh depending on tides, wind, or rainfall — so while the risk of serious electrical shock is generally understood to be less than that of freshwater — it is wise to err on the side of caution.

Marinas dealing with brackish waters should take the same precautions as those in freshwater locations. Bodies of water can be various degrees of brackish or fresh depending on tides, wind, or rainfall — so while the risk of serious electrical shock is generally understood to be less than that of freshwater — it is wise to err on the side of caution.

Marinas located within floodplains or with greatly fluctuating water levels — along rivers or ocean tidal areas — offer a different type of challenge for the electrical designer. The first issue is knowing where to place the electrical lines. According to the NEC, lines must be placed at a minimum of 2 feet above the highest water mark for fixed facilities, and have at least a 30-inch clearance above the water level at a floating pier or landing stage. A minimum of 12 inches is needed above the level of the deck as long as the floating pier moves vertically and not horizontally with rising water levels.

Case Study: Owensboro Transient Marina – Owensboro, KY

MSA professionals have been working with the city of Owensboro on the study and design of a new transient marina on the Ohio River, which can fluctuate up to 30 feet in height. To adapt to these radical changes in water level, MSA designed a system of five 80-foot gangways to safely transport visitors up and down the steep bluff to a series of floating docks. Some of these gangways are fixed structures that do not submerge; others are floating. In this scenario, engineers designed the electrical conduit to run from a utility vault on shore down through a braided, flexible steel cable, which is affixed beneath one of the fixed platforms before running down to the riverbed where it is tucked beneath the floating dock system in a hard conduit line, fully protected from the water. The braided cable is suspended along the gangway system with enough flex to allow it to flex and pull with the rising river and marina infrastructure.

Signed, Sealed and Delivered

There is good reason why an electrical engineer is involved in marina projects, and there should be no attempt to substitute the role out to a tradesperson, master electrician or journeyman — no matter their skill or tenure. It is, in fact, illegal. Electrical designs must be stamped by an actively licensed electrical engineer, and these designs should be conservative in their calculations. Being conservative means delivering the safest system possible.

What happens during the construction phase is, unfortunately, where a solid design can become compromised. Marinas should perform due diligence to ensure what has been drawn up is being dutifully delivered, with no shortcuts to time or cost. Electrical systems can be expensive, but the investment is one of safety — and peace of mind knowing the marina can be enjoyed without hesitation.

Dan Williams, PLA, ASLA, AHLP is senior landscape architect at MSA. He can be reached at dwilliams@msa-ps.com. Lance Teunissen, PE is electrical engineering team leader at MSA. He can be reached at lteunissen@msa-ps.com.

| Categories | |

| Tags |