Breaking Waves, Building Havens – A Guide to Protection Against Natural and Manufactured Events

Published on January 14, 2024Every size and shape of water body is prone to at least some type of turbulent activity. Therefore, every marina or waterfront facility is prone to at least some degree of damage. Whether created by mother nature and the increasingly severe storms of a changing climate or “manufactured” by the movements of barges, towboats, ships, or Great Lakes freighters, marinas need to understand the environmental inputs of their specific location to determine their level of vulnerability and what type of mitigation might work best.

Marina Studies and Surveys

An excellent first step is to conduct a thorough assessment of the marina property and behavior of the body of water associated with it. This should be performed by a seasoned marina designer or engineer. The study should include a bathymetric study to map out the details of underwater terrain, an analysis of wave and fetch direction, wave periods, littoral drift, and review of ground and soil conditions to determine what type of anchoring mechanisms and materials will be most effective. The goal of the study is to understand the limits of the water body — both high and low — and how things like precipitation, wind, wave, and ice activity might impact a marina’s infrastructure.

Once a study has been conducted, marina owners can work with a consulting engineer to review the data and determine which mitigation measure is best suited to its unique location, configuration, and environmental inputs. There is no one-size-fits-all solution, and marinas may decide upon a combination of structures to optimize protection. The menu of options includes breakwaters, wave attenuators, and shoreline revetment designs. Let’s take a look at each, what types of environments they work best in, and some projects that have found success utilizing them.

Breakwaters: Nature’s Shield

Breakwaters are best suited for larger bodies of water, those with significant wave activity, or with greater amounts of debris. They are designed to absorb and redirect the energy of incoming waves, providing a protective barrier for marinas and waterfront facilities. By reducing wave energy, these structures play an instrumental role in mitigating shoreline erosion, preserving the integrity of marina boundaries, and protecting the valuable assets within.

Breakwaters can take a handful of forms, from a rubble mound construction to a vertical seawall/bulkhead, composite structure, or floating system. They may be connected to land or freestanding. Being there isn’t a singular solution to fit every marina challenge, owners and operators should work with a qualified coastal, waterfront, or structural engineer to ensure the breakwater design will withstand forces over time without any negative impacts to the local ecosystem.

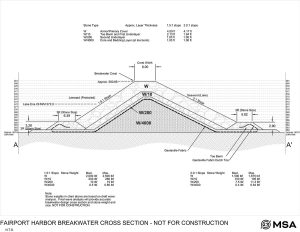

Rubble Mound Breakwaters consist of a core stone base of smaller rocks to build up the mound — up to two layers of underlayment — with larger rocks added to each level. This is topped with an armor stone cover — the heaviest and largest rock, designed to stay in place during the worst-case scenario caused by wave action. This design allows for the dissipation of wave energy, which prevents erosion and minimizes adverse impacts to marina infrastructure. When properly planned and implemented, rubble mound breakwaters can significantly reduce wave heights within marina basins, providing a calmer environment for docked and moored vessels.

Vertical Breakwaters are sometimes called seawalls or bulkheads. These are typically installed along the shoreline proper, in combination with the installation of stone, to deflect or absorb wave energy. They offer excellent protection against storms and accompanying shoreline erosion. Vertical breakwaters are generally composed of reinforced steel sheet wall or concrete materials durable enough to withstand the compound effects of wind and wave activity. They are particularly effective in areas exposed to storms, high winds, or strong tidal currents. The design of vertical breakwaters involves careful consideration of factors such as wave height, frequency, and soil composition — all informing the structure’s ability to endure the dynamic marine environment.

Composite Breakwaters combine the strengths of both rubble mound and vertical breakwaters to provide effective wave dissipation and great stability against erosive forces. These structures typically feature a core of rubble and a super structure of vertical wall.

Floating Breakwaters can be an economical solution for protecting small craft harbors or marinas with mild wave conditions and erosion concerns. However, they may be less effective in dissipating wave energy compared to the more robust hard-infrastructure options in larger wave conditions.

Caissons are another form of wave protection that are used more frequently in other countries. A caisson is a large concrete box that is placed on a rubble mound base. The size of the caisson creates a mass that the wave breaks over, allowing for calmer waters behind the structure. They are often used in ports or as part of larger industrial breakwaters and perform similarly to rubble mound breakwaters in the U.S.

Project Spotlight: Fairport Harbor Transient Marina

The Village of Fairport Harbor is located at the mouth of the Grand River on the shoreline of Lake Erie — a prime location for a new transient marina for the Lake Development Authority (formerly known as Lake County Ohio Port and Economic Development Authority).

In 2017, MSA and subconsultant FreshWater Engineering — now Anchor QEA — were hired to develop a master plan and report for the proposed marina, and in 2020, MSA and Anchor QEA were retained to provide final design and engineering services for a new transient marina at the site. This includes basin design to accommodate an influx of use, up to 150 slips for guest vessels up to 80’ in length, piers for three ODNR research vessels, shoreline protection to stabilize the basin edges, new docks and access gangways, fuel dock facility, restroom and shower facilities, upland design with stormwater management, and landscape furnishings. It also includes a robust new breakwater to protect the marina basin and its contents during both normal and design conditions.

As the marina is situated on the southern shore of Lake Erie, design conditions were of a more substantial nature and needed to accommodate the predominant winds of the Great Lakes as well as ice activity. A large 1,060-linear foot freestanding breakwater was identified as the structure most suitable for the task and construction is anticipated to begin in 2024.

Wave Attenuators: Tranquil Waters

Wave attenuators also come in different shapes and sizes, ranging from large, fixed structures to floating attenuators such as concrete dock systems or steel plates affixed to floating steel truss frame docks. In each, a surface — concrete or steel — extends deeper in the water to reduce wave energy as it passes through the upper limits of the water. As waves pass through a wave attenuator, they become smaller and less impactful by a combination of diversion and dissipation. Wave attenuators can be used for protection in marinas and harbors, along exposed shorelines, in navigation channels, ports, or other sensitive ecological areas. Their effectiveness depends on the careful study and consideration of factors such as wave patterns and periods, water depth, sedimentation loads, and environmental constraints. Proper design and engineering of these systems can optimize protection to meet each marina’s unique needs.

Fixed Wave Attenuators are stationary structures with interconnected elements such as submerged barriers made from rock or concrete — sometimes accompanied by floating structures anchored to the seabed. They are strategically placed to break the force of oncoming waves by absorbing and dissipating wave energy, resulting in greatly reduced wave heights and calmer waters within the protected area.

Floating Wave Attenuators rise and fall with water levels, which makes them more adaptable to changing conditions and more cost-effective than fixed systems. They are a good alternative for marinas or waterfront facilities with deep water, tight spatial constraints, or poor soil conditions — but those with smaller-sized waves. They can also be constructed in modules, allowing for flexibility in configuration and ease of transport.

Floating Systems can be constructed of a series of buoys or “pontoon” floats anchored by mooring lines or cables. Because these systems don’t have the same girth as most of their counterparts, they are less effective in handling anything other than mild marine environments.

However, some floating systems can be extremely robust and effective. In fact, some of today’s most popular floating wave attenuators consist of large concrete boxes or wing walls with the capability to integrate utility chases. Because of their bulk, these systems excel at absorbing the energy of incoming waves and pushing that wave energy beneath the attenuator structure where it slows itself down and settles on the other side. They are also multifunctional and can be finished with a concrete walking surface that can be embellished, stamped, or colored for aesthetic appeal.

An additional piece of “armor” involves affixing large, galvanized steel plates to the side of floating dock systems. These are secured just below the docks’ truss framework, extending vertically down into the water where they deflect turbulent water, thereby keeping the docks safe and stable — along with the watercraft that accompany them.

Debris Booms are an added protective feature for riverine environments or areas where debris might be in the water body. Debris booms are floating buoy systems that, when placed at an angle to a wave attenuator, collect trees and other debris before hitting the dock system.

Project Spotlight: Owensboro Transient Marina

The city of Owensboro is in southwestern Kentucky along the Ohio River — the third-largest river by discharge volume in the United States and the largest tributary by volume to the Mississippi River. It is a bustling recreational waterway as well as a working river, home to large commercial barge traffic. As such, marinas along the river feel the most adverse impacts from the wakes of large vessels — barges and towboats — that can easily churn up 4- to 5-foot waves when turning. While these waves dissipate to a degree before reaching docks or shorelines, they can still maintain 2 or 3 feet of height upon impact, which makes them large contributors to erosion and damage to marina infrastructure.

Staff from MSA developed a master plan for a proposed transient marina in 2014, and in 2021, provided design and engineering services for the development of the project in partnership with Brandstetter Carroll, Inc. The marina will be located riverside of the Owensboro Convention Center and will feature a 1,000-lineal-foot (500 lineal feet in Phase 1), 20-foot-wide floating wave attenuator dock system with an adjacent debris boom to capture the large amount of debris that tends to travel down the river. The project will also feature a new fueling station, floating restroom facility, fixed and floating gangway system designed to accommodate fluctuations in water level, dockside electrical, and potable water services.

Shoreline Revetment: Protecting the Perimeter

Revetment is the final safeguarding mechanism for marinas and waterfront facility owners to protect against the dynamic environments of tides, storms, boat wakes, and other water-induced pressures. Shoreline revetment methods range from the strategic placement of riprap to the implementation of thoughtful (and appealing) vegetative plantings to shield against erosion and contribute to the overall safety, longevity, and management of our coastal infrastructure. The type of revetment chosen should be based on each facility’s specific shoreline conditions and challenges, including consideration of wave patterns, ferocity, and soil composition.

Riprap consists of large, durable stones or concrete blocks placed along the shoreline to absorb wave energy and prevent erosion. Similar to rubble mound breakwaters, riprap revetment consists of underlayment and armor stone layers. The irregular finish of angular stones results in a porous barrier that allows the waves to dissipate — reducing shoreline scouring.

Vegetative Revetment utilizes natural vegetation such as perennial plants and grasses with extensive root systems to bind the soil, stabilize the shoreline, and prevent further damage from erosion. This approach alone will not combat the forces of large weather or wave events but can be used in tandem with riprap or in places that do not require such robust solutions. Vegetative revetment can also enhance the visual appeal of a marina and promote biodiversity while providing practical benefits as well.

Project Spotlight: Beach Drive Coastal Resiliency

The village of Fox Point is a 2.8-square-mile suburb of the Milwaukee Metropolitan Area along the western shore of Lake Michigan. Between October 2019 and January 2020, two significant storm events caused the near-record-high levels of Lake Michigan to swell even greater — with extreme winds and waves reaching 6-10 feet in height. These compound storm events significantly altered the shoreline along Beach Drive, receding 5-8 feet in most locations, toppling trees, clogging storm sewer pipes, and encroaching dangerously close to Village lift stations and sanitary sewer systems. The village knew it was time for action.

In March of 2021 the village hired the team of MSA and Anchor QEA to develop a new coastal resiliency design to be implemented in 2022. Over 35,000 tons of revetment stone totaling over 1,500 truckloads was delivered and placed along 2,500 feet of the shoreline. The stormwater conveyance system was fortified and improved to include green infrastructure, such as bioretention ponds, which treat water and remove contaminants before the water enters. New access points to the water were also added, allowing the public to safely and consistently enjoy the waters of Lake Michigan for decades to come.

Building Resilience

Safeguarding marinas against the unpredictable forces of both natural and manufactured events necessitates a proactive approach rooted in comprehensive studies and strategic implementation of protective measures. By conducting thorough assessments of local environmental conditions and potential risks, marina operators can make informed decisions about integrating breakwaters, wave attenuators, or shoreline revetment practices into their infrastructure. These measures not only enhance the resilience of marinas but also contribute to the long-term sustainability of coastal properties — ensuring a safer and more secure environment for both vessels and the surrounding community.

Dan Williams, PLA, ASLA, AHLP is senior landscape architect at MSA. He can be reached at dwilliams@msa-ps.com. Marcus Rue, PE is project manager at MSA. He can be reached at mrue@msa-ps.com

| Categories | |

| Tags |