Fuel Dock Safety: Complacency Kills

Published on February 24, 2021Editor’s Note: This is just a small amount of the data included in NFPA 30A. It is recommended that all fuel dispensing facilities purchase, read, and review this document thoroughly with their staff. Original copies can be obtained from NFPA headquarters, 1 Batterymarch Park, P.O. Box 9101, Quincy, MA 02269-9101; email: stds_admin@nfpa.org.

I don’t really need to show you a video of a boat explosion after it was improperly fueled at a fuel dock to get your attention, or do I? Being involved in marine claims for over 35 years, I can tell you that at least twice each year, I have either investigated a case or handled a claim involving fuel being pumped into a rod holder resulting in either a fuel spill and environmental catastrophe or worse, an explosion resulting in heavy damage to the vessel, dock, serious injury and sometimes death. So, am I serious when I say this is important stuff? You bet I am.

Not to stereotype, but the days of high school kids in shorts and tee shirts manning fuel docks is over. That is unless you have really well trained, experienced, safe, and responsible high school kids working for you. If you have a busy fuel dock, it is perhaps the biggest single stream of revenue at your facility. A single accident can take that all away in an instant.

For this article, and a follow up article, I am going to focus on two different types of losses as well as prevention:

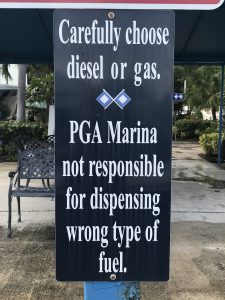

First, is the simple, “Gas in Diesel” or “Diesel in Gas” scenario. This sounds so “simple stupid” but it happens dozens of times a year and it may have even happened to you (you can be honest… no one is watching you nod your head). While this may be a simple mistake, the consequences can range from minor damage to very serious and expensive repairs.

Second, is the unfortunate and often very serious consequence of not following the proper rules and regulations regarding the fueling of motor vessels at your “Motor Fuel Dispensing Facility.” Improper fueling (primarily with gas) can result in fire, explosion, catastrophic damages and, as noted above, death.

Gas or Diesel

So, let’s talk the easy stuff first. Putting the right fuel into your customer’s boat. As a claims manager, my adjusters and I have to review cases brought forward by other carriers (subrogation) against the marinas we insure for cases involving alleged improper fueling. “Gas in diesel” or “diesel in gas” can result in, at a minimum, the need to pump the fuel tanks and dispose of the contaminated fuel to more complex repairs to engines (diesel engine injectors don’t really like gas). In my experience, however, all of these improper fueling have one thing in common… the boat owner pumped the wrong fuel into his or her own boat. That is right, you, the marina owners who sold the fuel, are being blamed for putting the wrong fuel in the customer’s boat, but you did not put it into their boat, THEY DID. That does not seem to matter anymore. No one ever accepts responsibility; it is always someone else’s fault. Welcome to the world of subrogation.

We have a current case where there is a woman on the foredeck of the boat as it is pulling in saying that they want “gas, a pump out and ice.” They pull up in front of the gas pump (the diesel pumps are 80 feet away), ask for gas, the gas hose from the dispenser (you know, the one with the 3” high letters that say “Gasoline”) is handed to them and they proceed to fill not one, but both tanks with gas. They got the pump out and ice and drove away. Remember, I said that diesel engines don’t like gas? Well, theirs didn’t and now our insured is being blamed for a couple of hundred thousand dollars of damage. I could recount this several times over. The names have been changed, but the fact pattern is often the same. So, what do we, as an industry do to prevent this type of accidental fueling from occurring? A couple of simple things come to mind.

Three-Syllable Rule

Train your staff the three-syllable rule. Your staff can’t be asked to know what type of fuel every boat needs. That is the boat owner’s/operator’s responsibility. Period. But we can help them not screw up, right? The three-syllable rule is as “Keep it Simple Stupid” (KISS) as it comes. Train your staff to ask each operator: “Do you want ‘GAS-O-LINE’ OR ‘DIE-SEL-FUEL’?” If they screw that up, they deserve the headaches. Next, be sure your pumps are well marked. Many facilities have the diesel fuel set far away from the gas but that is not as necessary as good, clear, and legible signage on each dispenser. NFPA requires 3” block lettering prominently displayed on the pump that says “GASOLINE” or “DIESEL FUEL.” The hoses should be color-coded. Most standards call for green for diesel and black for gas but you should be sure to check your state regulations to be compliant. Fuel nozzle covers should be green for diesel and I personally think red for gas. You may also look into nozzle covers or tags to attach to them that say “diesel” or “gas.”

It goes without saying, that unless your state requires your staff to actually fuel the boat, your fuel dock crew member should hand the pump to the boat owner/operator to fuel his or her own boat. ABYC requires that the fuel fills on deck be clearly and permanently marked (H24.13.6 for gas and 33.12.3) but unfortunately, unlike your car, the design of the fills can allow the introduction of the wrong fuel into the tank because, while there is a standard for the opening of the gas fill(1-1/8” minimum), that standard does not exist for diesel fills. We expect that boat owners should be capable of pumping the correct fuel into their boat, so that is why I guess there are no further safeguards at the fill location, but perhaps we need to rethink this as an industry.

All boiled down… train your staff to use the three-syllable rule and confirm, more than once if necessary, what type of fuel your customer wants, but more importantly, needs. This and proper signage and color-coding are essential to keep the very highest of standards at your fuel dock.

NFPA Codes

Now, on to the really bad stuff. You may be familiar with NFPA 303, the Fire Protection Standard for Marinas and Boatyards. But how many of you know about NFPA 30A Code for Motor Fuel Dispensing Facilities and Repair Garages (2018)? Be honest. Not many hands went up on that one, right? Well, if you have a fuel dock or dispense fuel in any capacity at your facility, you must be compliant with this standard, period. Are NFPA Codes law? No, they are not. Do you need to comply? Yes, you do unless you can show that compliance with your local AHJ (Authority Having Jurisdiction) supersedes NFPA codes. Why? Well, if anything goes south, NFPA 30A is going to be the standard that you are held to in most courts of law. So, lets dive in…

NFPA 30A 3.3.11 defines a Motor Fuel Dispensing Facility as: “That portion of a property where motor fuel is stored and dispensed from fixed equipment into the fuel tanks of motor vehicles or marine craft or into approved containers, including all equipment used in connection therewith.” 30A 3.3.11.4 defines a Marine Motor Fuel Dispensing Facility as: “A motor fuel dispensing facility at or adjacent to shore, a pier, a wharf, or a floating dock where motor fuels are dispensed into the fuel tanks of marine craft.” So, which are you? If you are inland with no waterfront, you’re the former, if you are on the water and dispense fuel from a dock, you are a Marine Motor Fuel Dispensing Facility.

This distinction is important because the rules, while similar, have subtle differences. For the purposes of this article, we are going to discuss the latter.

Some basics: Both require self or automatic closing dispensing nozzles with no “latch-open device.” All require that hoses over 18’ in length must be secured to prevent damage. Most often we see this as reels of hoses. Both standards require that the dispensing of fuel must be done so into only approved containers. The location of those containers during the fueling process is very specific in the Marine Chapter. Fire extinguisher placement (30A 9.2.5.2) is per NFPA 10 for both land and marine applications. Lastly, warning signs need to be placed at the motor fuel dispensing locations, per code (30A9.2.5.4).

Chapter 11: Marine Fueling

Some key takeaways to remember include:

• 11.4.4 Dispensing devices shall be located so that the exposure to all other operational marina or pleasure boat berthing area facilities is minimized.

• 11.4.5 No vessel or marine craft shall be made fast to any other vessel or marine craft occupying a berth at a fuel dispensing location during fueling operations.

• 11.4.7 – Each marine motor fuel dispensing facility shall have an attendant or supervisor on duty whenever the facility is open for business. The attendants’ primary function shall be to supervise, observe and control the dispensing of liquids.

• 11.8.3 Portable containers of 12-gallon capacity or less shall not be filled while they are in or on a marine craft.

• 11.10.1 – The following shall be the responsibilities of the attendant: (1) – Prevent the dispensing of Class I liquids into portable containers that do not comply with 11.8.2; Be familiar with the dispensing system and emergency shutoff controls; (3) Ensure that the vessel is properly moored and that all connections are made; (4) Be within 4.6 m (15 ft) of the dispensing controls during the fueling operation and maintain a direct, clear, unobstructed view of both the vessel fuel filler neck and the emergency fuel shutoff control.

• 11.10.3 – No smoking on, near, or off boat.

• 11.10.4 – All engines, motor, fans and bilge blowers shut down before fueling, all open flames extinguished, all galley stoves extinguished, and all ports, windows, doors and hatches closed.

• 11.10.5 After the flow of fuel has stopped the following shall occur: The fill cap shall be tightly secured; any spillage wiped up immediately; if Class 1 liquid has been delivered, the entire vessel of marine craft shall remain open; bilge blowers shall be turned on and allowed to run for at least 5 minutes before starting any engines or lighting galley fires.

• 11.10.6 – Each Class 1 fuel tank must have a separate fill.

• 11.10.7 – Vessel owners shall not offer their vessels for fueling unless: the tanks are properly vented, all fuel systems are designed, installed and maintained in compliance with manufacturer specifications; communication has been established with respect to the capacity of the fuel, amount of fuel on board and the amount to be taken on board; and that the bonding and grounding systems have been maintained to manufacturer specs. Nowhere, however in this rule does it specify that the owner must properly communicate what type of fuel is required… to take it back to the top “Gas-O-Line” or “Die-Sel-Fuel.”

Now let’s take a moment to discuss some of these in the context of running a very busy fuel dock on a Saturday morning in July. No rafting up boats at the fuel dock. I don’t care how busy it is, don’t do it. I have seen this many times and it is dangerous. Do you make the guy with the 6-gallon steel or plastic tank strapped to his Boston Whaler 16 Montauk remove the tank in order to fill it? Well, under 30A you must fuel that tank not only off the boat, but preferably not on the dock over the water. Ideally, you should have a pump on land, where the tank can be set on the ground (so it is grounded) to eliminate the potential for a static buildup – which could cause an explosion. No matter what the reason – really – don’t let anyone put fuel in a non-approved portable container. And certainly not while on the boat.

I think we got the “no smoking” thing down, I sure hope so by 2021 but how many follow 11.10.4 by not only shutting down the engines, but also shutting down breakfast on the stove and shutting all doors, windows, hatches and ports? Really? On a hot summer morning? This rule is all about minimizing vapor collection. Maybe it is a bit over the top, admittedly, but it is the rule.

One interesting thing 30A does not tackle are bilge pumps. How often have you witnessed fuel dispensed, by mistake, into that rod holder we were talking about earlier only to have the automatic bilge pump activate and start to pump the fuel overboard. This could cause a pollution headache in the case of diesel or worse, an explosion because of an arc in the positive lead to the pumps float switch in the case of gas.

Well-Managed Fuel Dock

My best advice to summarize is that your fuel dock, if managed well and professionally, should take all that NFPA 303 and especially 30A to heart and make it your fueling Bible. Your staff needs to be incredibly well trained and disciplined. All customers must follow the rules, or they can fuel up elsewhere. NFPA, among other things, requires that before fueling, make sure that the boat is off; the bilge blowers are off; the engine hatch is closed; the cabin hatch is closed; and the bilge pumps are off. Confirm prior to fueling if the vessel requires “Gas-O-Line” or Die-Sel-Fuel.” Let the boat operator fuel his or her boat. Observe the fueling process as best as possible. Once fueling has been completed and the hose has been returned to the dispenser, the bilges need to be visually examined, the bilge blowers engaged and run for the specified time. Systems should be restarted or energized only once it has been determined that there is no spilled fuel, odors or hazards present. Complacency kills.

A Note From The Author: Regarding the use of bilge blowers, I question the wisdom of not having them running constantly during the fueling process. When you energize, in this case, a DC circuit, there is a possibility of a spark if there is a loose wire connection. Because the Standard suggests that the blowers should be off, simply energizing that system could result in an explosion. In my experience, leaving the bilge blowers running during the fueling process does a few things. It continually removes fuel vapor from the bilge area and it eliminates that “spark potential” when the bilge blowers are engaged.

| Categories | |

| Tags |